Welcome to visit Xunmao Technology (Dongguan) Co., Ltd. website!

Hotline:18138203997

Case

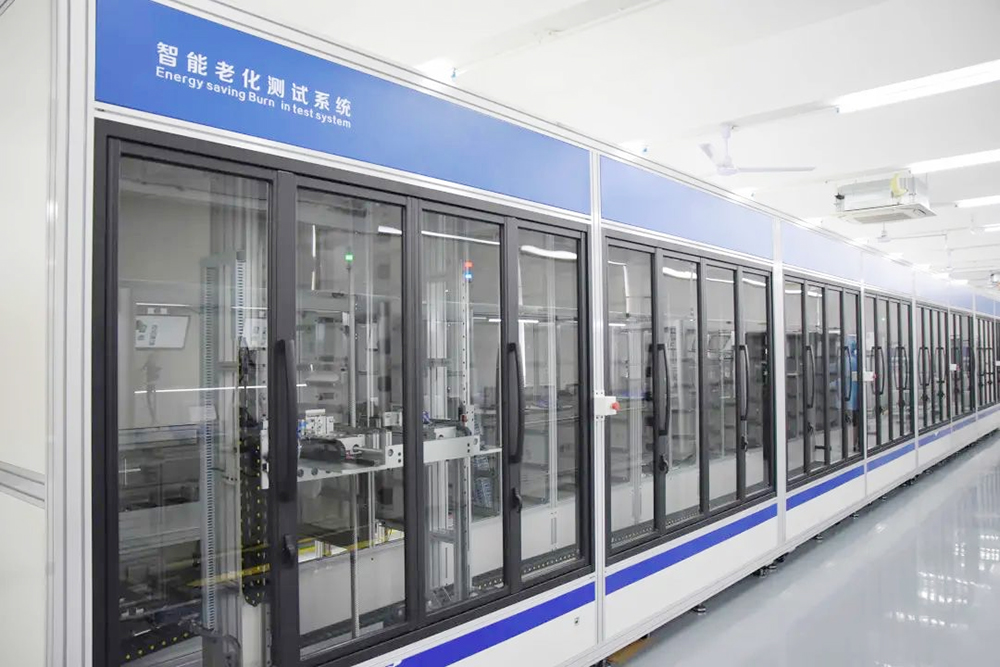

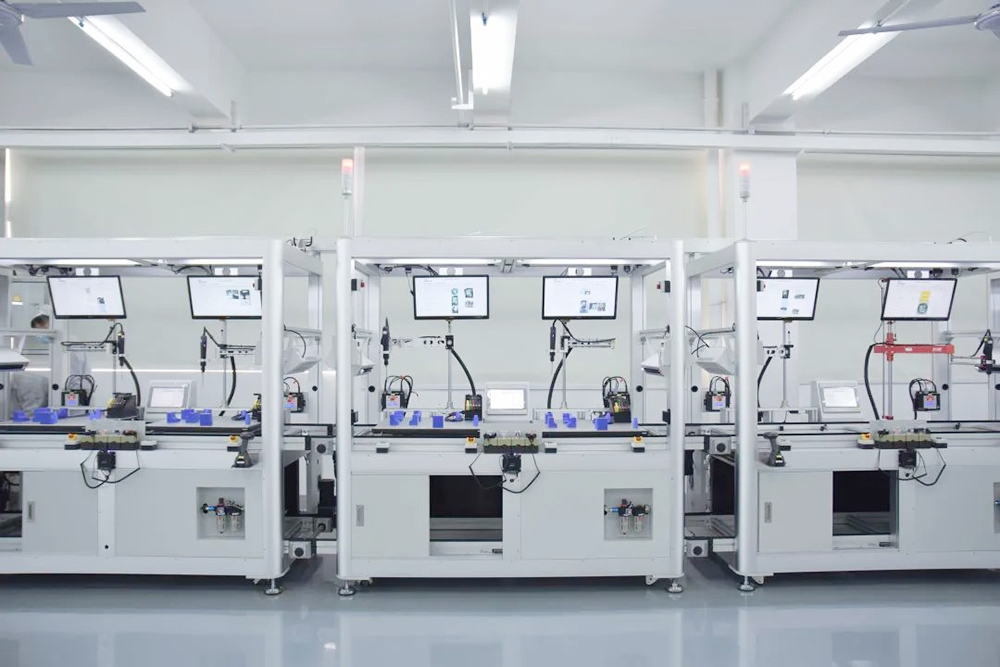

CaseThe two newly introduced production lines are based on the concept of "automation, informatization, and intelligence", and are designed to automatically complete assembly, transmission, pressure resistance testing, aging testing, and other processes for AC pile products. After the production line was put into use, the average monthly production capacity of AC piles reached 60000 units, greatly saving labor costs, improving production efficiency, and enhancing product quality.

A highly automated production mode can greatly reduce manual input. Compared with traditional production methods, the new production line has a high degree of automation, strong quality stability, excellent digitalization, and stronger efficiency creation ability. The operation of this production line has enabled customers to achieve a new leap in charging pile production capacity, quality stability, and market adaptability, injecting new impetus towards digitization and intelligence.